About NISSEI FN 7000 360 TON MACHINE

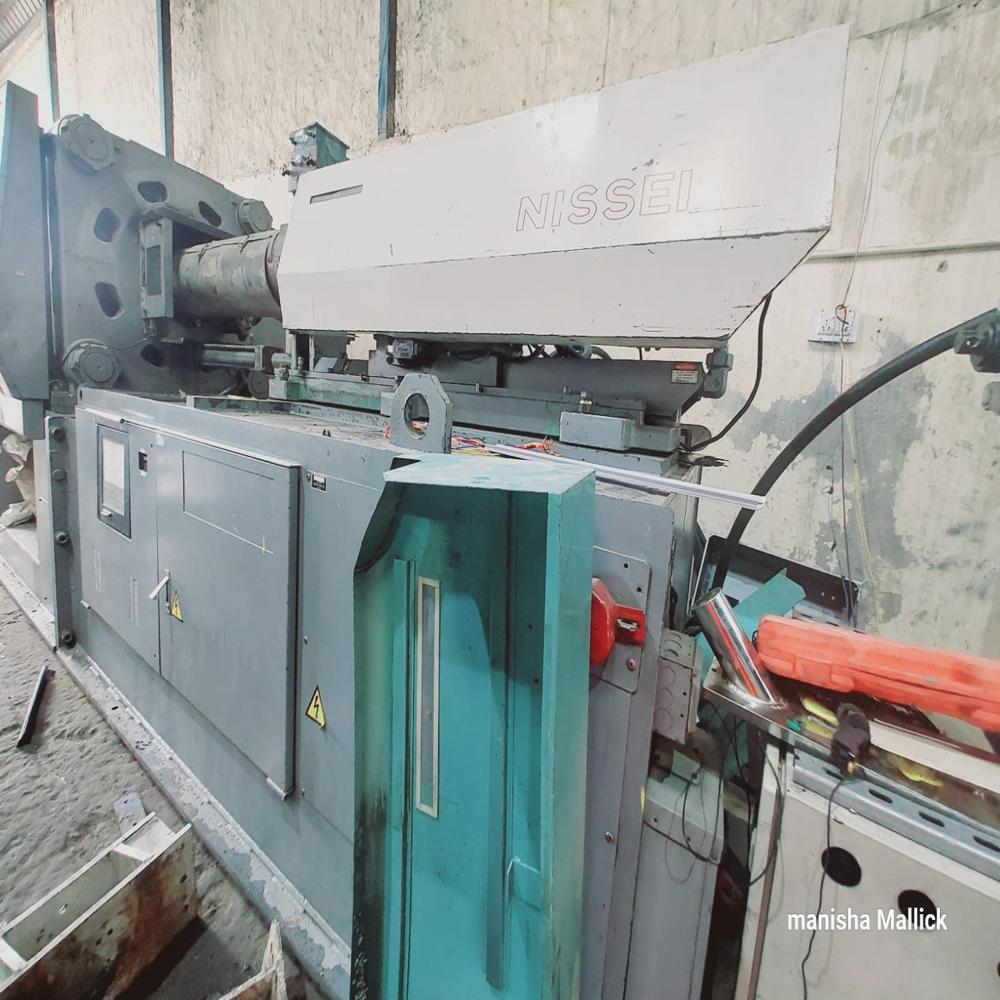

NISSEI FN 7000 360 TON MACHINE

The NISSEI FN7000 is a high-performance injection molding machine built for large-volume production. With advanced hydraulic precision and robust clamping force, it ensures consistent molding quality.

Ideal for automotive, industrial, and heavy plastic parts, it handles complex molds with ease.

Its energy-efficient design and user-friendly control panel make it a perfect choice for modern factories.

Reliable. Powerful. Efficient that the NISSEI FN7000.

Advanced Injection Molding TechnologyThe NISSEI FN 7000 360 Ton Machine utilizes advanced aluminum alloy construction and a PLC control system to offer reliable, automated injection molding. Designed for large scale manufacturing, its high precision, rapid response, and powerful clamping force guarantee high-quality outputs and consistent product quality.

Superior Performance and EfficiencyHigh-speed operations, smooth running mechanics, and flexible mold thickness capacity make the FN 7000 suitable for diverse manufacturing requirements. Its efficient injection system handles up to 400 g/s, while the heating power (20-28 kW) ensures stable processingideal for demanding production environments where speed and quality matter.

User-Friendly and Versatile OperationWith its horizontal style, automatic features, and computerized controls, the NISSEI FN 7000 provides ease of use for operators. The machine is adaptable for various injection molding needs and benefits from robust safety features, a wide ejector stroke range, and options for standard or customized colors to match facility preferences.

FAQs of NISSEI FN 7000 360 TON MACHINE:

Q: How does the PLC control system benefit the operation of the NISSEI FN 7000 360 Ton Machine?

A: The PLC control system enables precise and automated functioning, ensuring accurate process parameters, reduced manual intervention, improved consistency, and efficient troubleshooting, which ultimately results in higher productivity and product quality.

Q: What types of plastic products can be manufactured with this injection molding machine?

A: The NISSEI FN 7000 360 Ton Machine is suitable for producing a wide range of plastic items, from automotive components to consumer goods and industrial parts, thanks to its flexible clamping force, adjustable mold thickness, and high injection capacity.

Q: When should routine maintenance be performed on this machine?

A: Routine maintenance should follow the manufacturers guidelines, typically involving daily and weekly inspections of key components such as the injection unit, clamps, and hydraulic system to ensure optimal performance and extend the machines lifespan.

Q: Where is the NISSEI FN 7000 360 Ton Machine primarily used?

A: This machine is primarily used in plastic manufacturing facilities, automotive parts suppliers, and general industrial environments across India, serving importers, suppliers, and traders who require efficient and reliable injection molding solutions.

Q: What is the process for changing molds on this machine?

A: Changing molds involves stopping the machine, loosening the clamp system, removing the current mold, positioning the new mold within the specified thickness (200-700 mm), securing tie bars, and recalibrating operational settings using its PLC interface for optimal production.

Q: How does the high-speed response feature improve the manufacturing process?

A: High-speed response allows for rapid injection cycles and quick adjustments, reducing production time per item, minimizing downtime, and increasing overall output without compromising the quality of the molded parts.

Q: What are the main advantages of using an aluminum alloy structure in the FN 7000 machine?

A: Aluminum alloy provides excellent durability, lighter weight for easier transportation and installation, and resistance to corrosion, all of which enhance machine longevity and reduce maintenance requirements.